### Laminated Particle Board Vs MDF

When it comes to choosing materials for furniture or other woodworking projects, two common options are laminated particle board and Medium Density Fiberboard (MDF). Both materials offer unique benefits and drawbacks that make them suitable for different applications. To help you make an informed decision, let’s compare the features of laminated particle board and MDF based on their structure, strength, and usability.

#### Structure and Composition

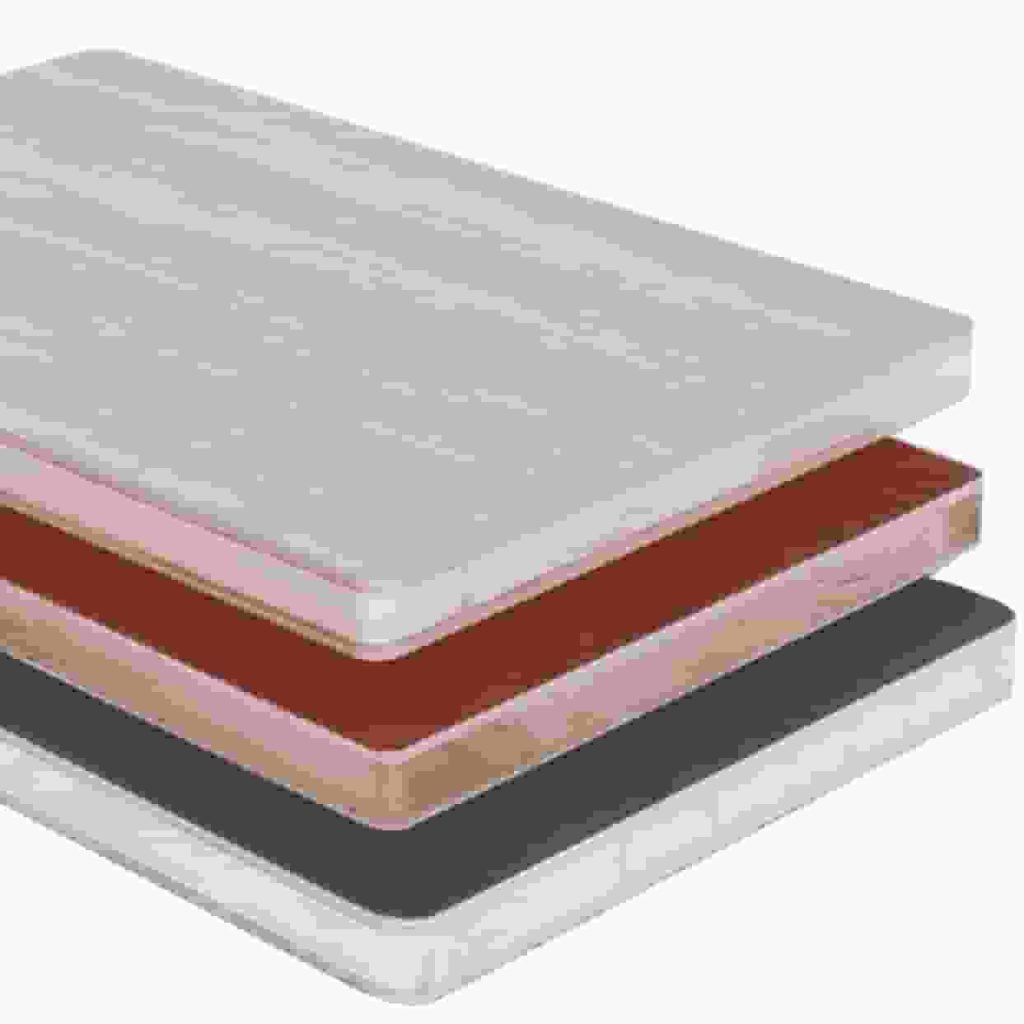

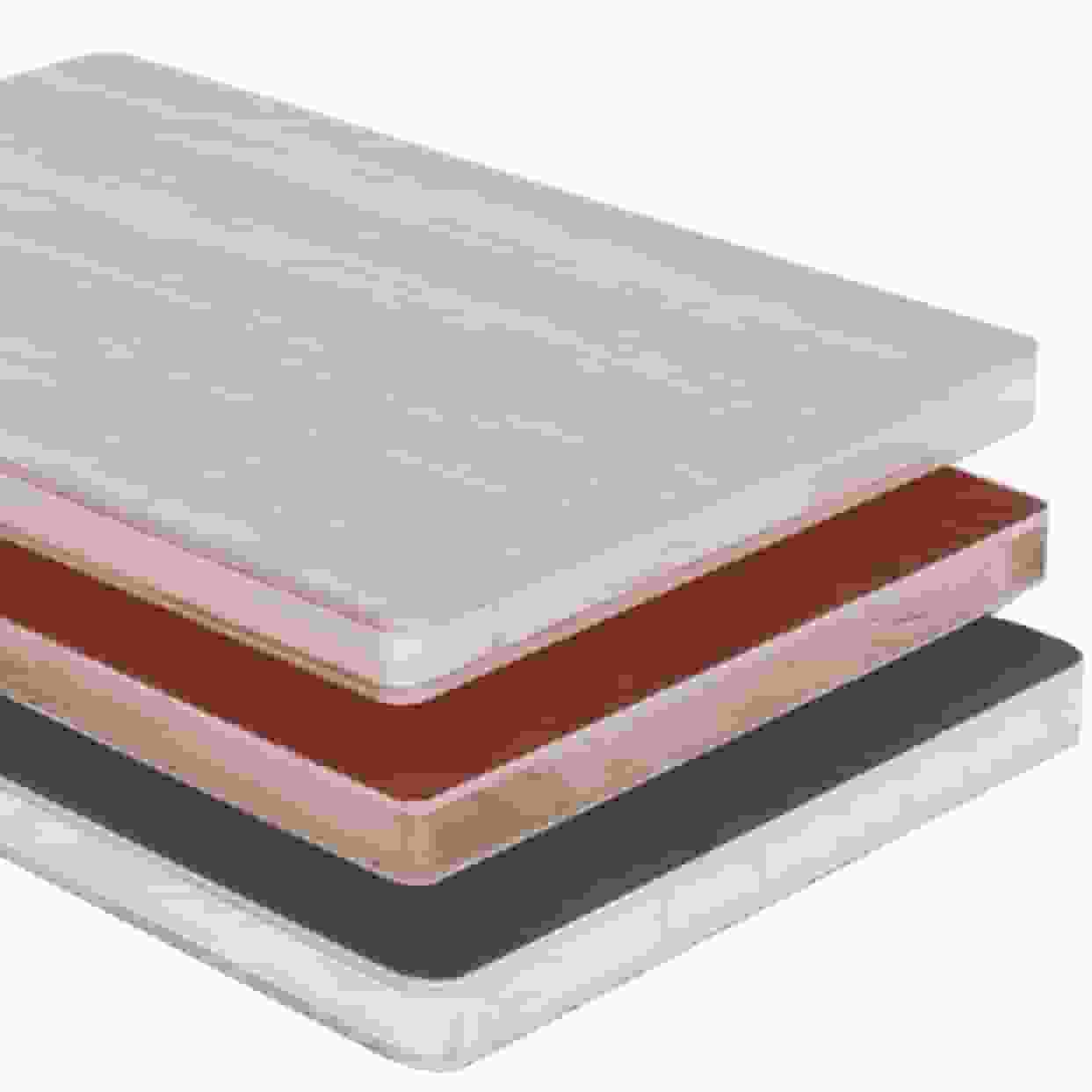

Laminated particle board, also known simply as particle board, consists of tiny wood particles bonded together with a resin and then covered with a layer of melamine, veneer, or another decorative surface. The result is a lightweight board with good visual appeal. On the other hand, MDF is made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and a resin, and forming them under high pressure and temperature into panels. This process results in a denser, more consistent material compared to particle board.

#### Strength and Durability

The structure differences lead to variations in strength and durability between the two materials. Laminated particle boards are generally less strong and more prone to damage from water exposure or heavy impacts. They often have a tendency to delaminate, which means the layers can separate over time, particularly when subjected to moisture. In contrast, MDF is denser and more uniform, offering higher structural integrity and resistance to warping. It does not delaminate like particle board but is more prone to expansion when exposed to moisture without proper sealing.

#### Working with the Materials

Both laminated particle board and MDF can be cut, drilled, and shaped using standard woodworking tools, but their differences affect how they respond to these processes. For instance, MDF has a smoother surface and doesn’t produce splintering, making it ideal for painting. However, sawing or sanding MDF releases fine dust that is harmful if inhaled, requiring careful use of respiratory protection. Laminated particle board, with its outer layer of veneer or melamine, offers a surface ready for light sanding and finishing, but special blades may be needed to prevent damage during cuts.

#### Examples of Use

To illustrate practical uses for each material, consider a few examples: A 4X4 MDF board could be used for creating a clean, painted base in craft projects where a precise finish is required. Meanwhile, a 5 Foot MDF Board might serve as the backdrop for a theatrical set due to its large size and easy paintability. For smaller scale applications, such as shelving or drawer components, a 25mm MDF Bunnings product might be preferred because of its ready availability and cost-effectiveness.

In conclusion, your choice between laminated particle board and MDF should be influenced by the demands of your project concerning aesthetic appeal, strength requirements, and how you plan to work with the material. While both have their advantages and limitations, understanding their key differences allows you to select the best fit for your needs.