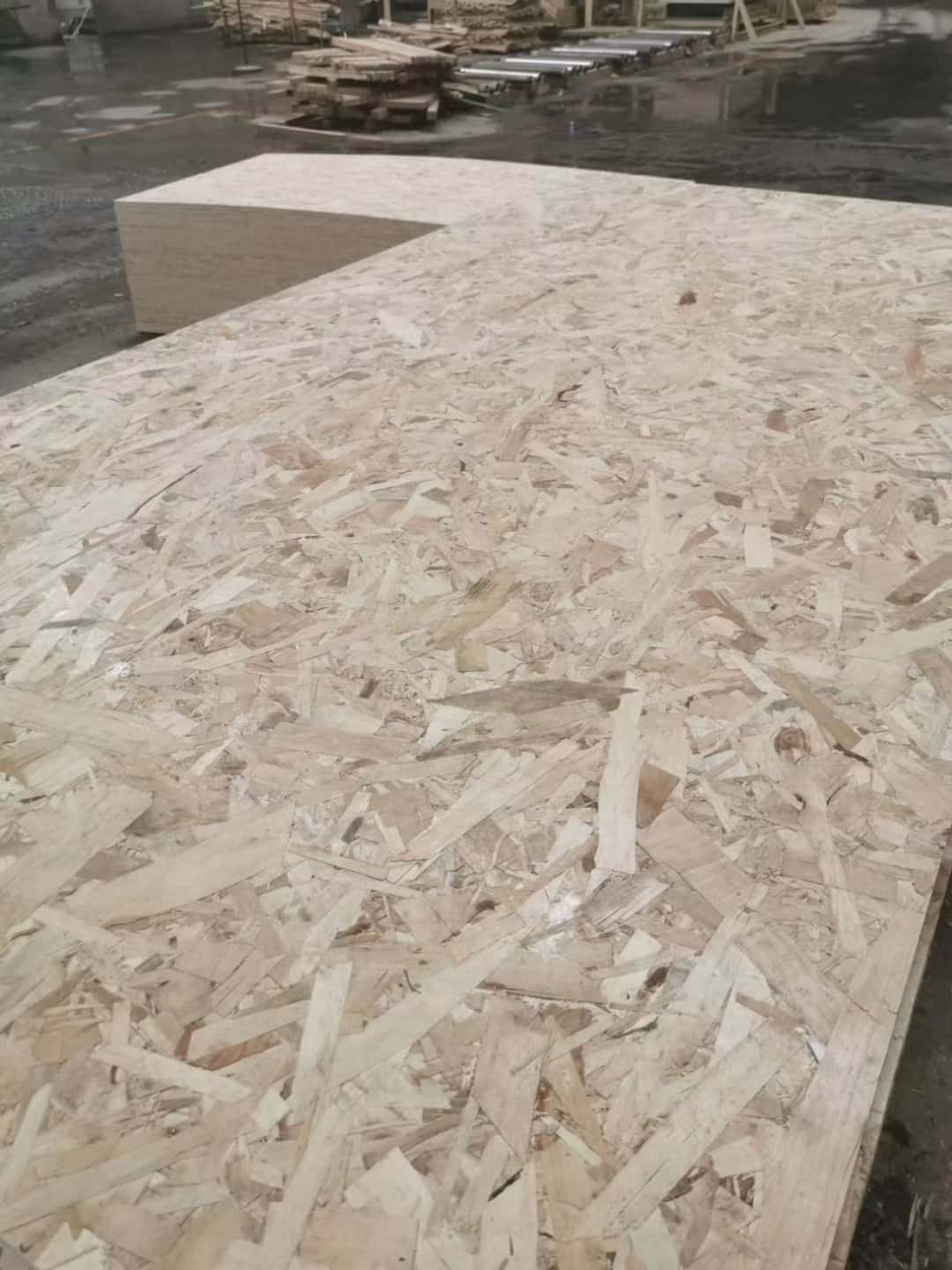

**Oriented Strand Board: How It’s Made**

Oriented Strand Board (OSB) represents a significant innovation in the world of wood-based panels. Known for its structural integrity and versatility, OSB has become a staple in construction and manufacturing industries. This article aims to demystify the production process of this robust material, with a focus on various types such as Laminated Strand Board, 5/8 OSB Board, 3/8 OSB Board, 4 X 8 OSB Board, and 1/8 OSB Board.

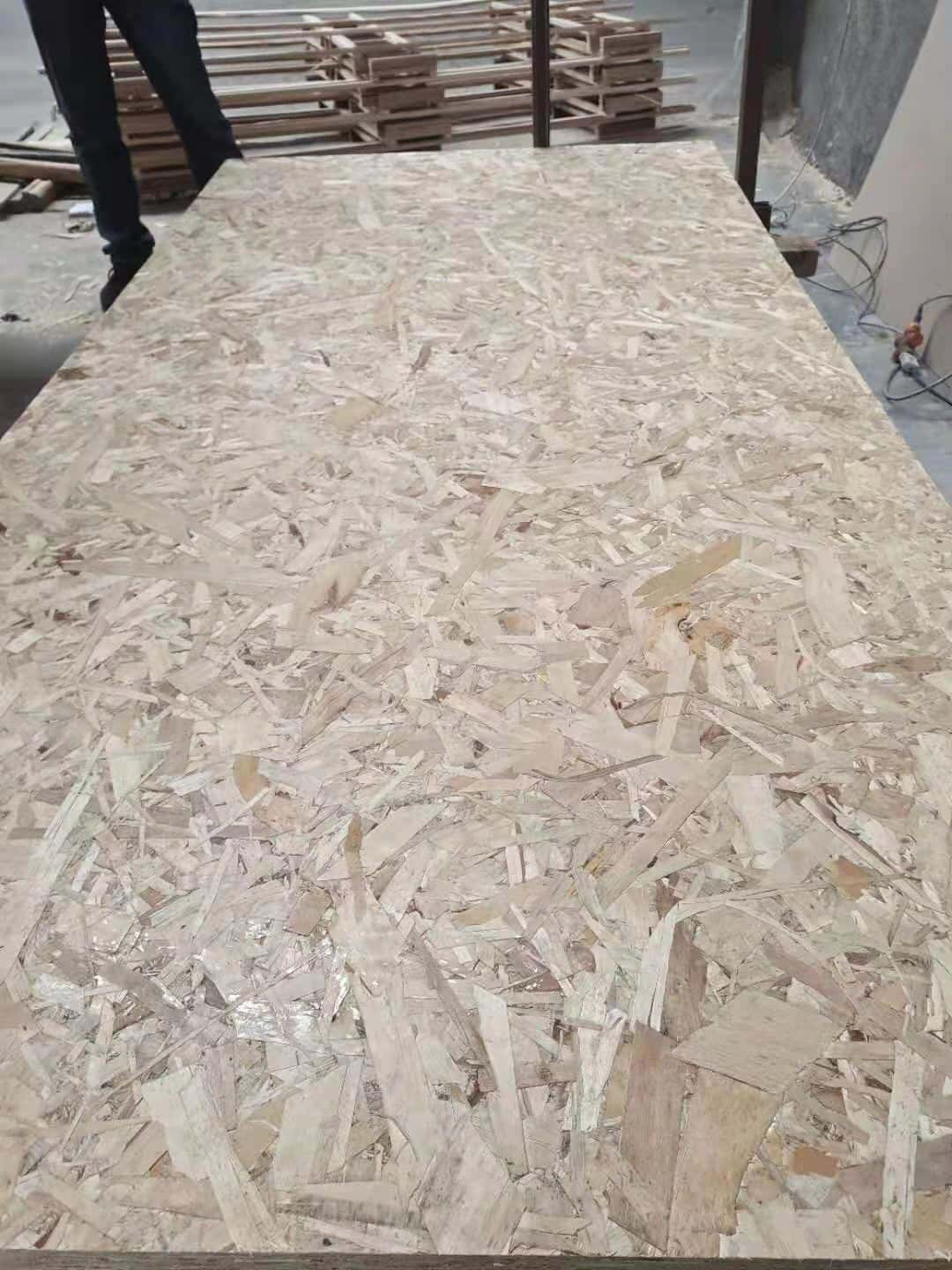

The journey of making OSB begins with raw materials selection. Logs, predominantly from softwood trees like pine, spruce, or fir, are chosen for their strand-forming abilities. These logs undergo debarking to remove the outer layer, ensuring that only the high-quality wood is used for producing strands. Once debarked, the clean wood is then sliced into thin, flat strands of specific dimensions. Each strand’s thickness can vary according to the type of board being produced, ranging from a stout 5/8 of an inch to a more delicate 1/8 of an inch.

Strand alignment plays a vital role in defining the final properties of the OSB. Long strands are aligned in a specific direction during the laying process, which is typically done in several layers. The bottom layer usually consists of strands placed perpendicular to the panel’s length, while subsequent layers alternate the orientation, creating a cross-plied structure that enhances strength and stability. This methodical layering is crucial for achieving optimal performance in different types of boards, such as the sturdy 5/8 OSB Board or the flexible 1/8 OSB Board.

Adhesive application follows the careful placement of these strands. A waterproof adhesive, typically a type of modified isocyanate, is evenly applied to each layer. This adhesive is critical because it binds the strands together and provides moisture resistance, making the OSB suitable for various conditions. For example, a 4 X 8 OSB Board often used as sheathing in roofing must endure harsh environmental changes, and the adhesive ensures this resilience.

Once the adhesive is spread across the strands, they are pressed together using heat and pressure in a process known as hot pressing. This stage not only bonds the strands firmly but also shapes the panel into its intended size and thickness. Whether it is for producing a densely packed 5/8 OSB Board or a thinner 1/8 OSB Board, the precision of this step is paramount.

After pressing, the newly formed OSB panel is cooled and conditioned to ensure its stability before being trimmed to standard sizes. Sanding may follow to smooth the surface, preparing it for applications that require a finished face, such as in the case of Laminated Strand Boards used for furniture components.

Lastly, the panels are inspected and graded according to their quality and intended use. From here, they are ready to be distributed and incorporated into various end products, serving roles from structural members in houses to elements in sophisticated laminated structures.

In summary, the making of Oriented Strand Board involves a meticulous series of processes, starting from selecting the right logs, cutting them into strands, aligning these strands strategically, applying adhesive, pressing them under heat, and finally, finishing and grading. The result is a highly durable and versatile material that comes in numerous variations, each tailored for specific functions and environments.