**MDF Board Laser Cutting Machine: Revolutionizing the World of Crafts and Prototypes**

The world of crafts and prototypes has been forever changed with the advent of the MDF board laser cutting machine. This revolutionary technology allows for precision cuts on a variety of MDF (Medium Density Fiberboard) board sizes, making it an indispensable tool for designers, artists, and engineers alike.

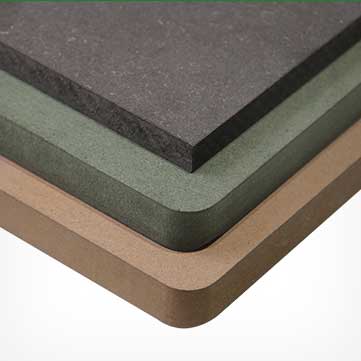

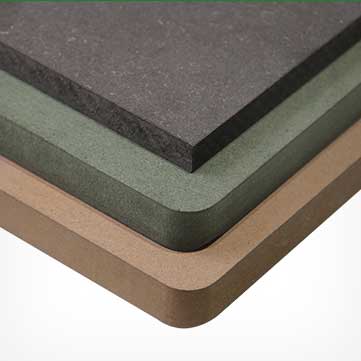

One of the most significant advantages of the MDF board laser cutting machine is its ability to work with different thicknesses and sizes. Whether you need to cut a 3mm MDF board for a delicate craft project or a robust 6 x 4 MDF board for a more extensive model, this machine can handle the task with ease. The same applies to the 3/8 MDF board and even thinner profiles like the .5 MDF board, showcasing the machine’s adaptability and versatility.

Another feature that sets the MDF board laser cutting machine apart is its compatibility with various board dimensions. An 8 x 5 MDF board, for instance, can be precisely cut, ensuring that each piece fits perfectly for whatever project you’re working on. This level of accuracy is crucial for projects that require multiple parts to fit together seamlessly, saving time and reducing waste.

The process of using an MDF board laser cutting machine is surprisingly user-friendly, thanks to advancements in software technology. Designers can create their patterns on computer programs specifically designed for laser cutting. These programs can translate the digital design into precise instructions for the laser cutter, streamlining the process from concept to physical form with minimal human intervention.

In terms of application, the possibilities are virtually endless. From intricate jewelry boxes to life-sized architectural models, the MDF board laser cutting machine offers a quick, accurate, and efficient means of production. Artists appreciate the fine detail that can be achieved, while engineers value the machine’s capacity for repeatable, precise cuts that are essential for prototyping and model-making.

Moreover, the use of MDF boards with a laser cutting machine also opens up opportunities for personalization and customization. With the ability to cut unique shapes and patterns, creators can produce one-of-a-kind pieces that cater to specific tastes or requirements, further expanding the creative horizon.

As technology continues to advance, so too does the capability of the MDF board laser cutting machine. Integrating automation features and enhancing software capabilities ensure that this tool remains at the forefront of innovation. The future holds even more potential as these machines become faster, more precise, and accessible to a broader range of users.

In conclusion, the MDF board laser cutting machine represents a leap forward in the world of crafts, designs, and prototyping. Its ability to work with a variety of MDF board sizes and thicknesses, coupled with its precision and ease of use, makes it an invaluable asset for anyone looking to bring their creations to life with unparalleled speed and accuracy. As we look ahead, there’s no doubt that this technology will continue to shape and improve the ways in which we construct and create, pushing boundaries and redefining what’s possible in the realm of design and craftsmanship.