Plywood is a versatile engineered wood product used across various industries, from construction and furniture-making to interior decoration and exterior finishing. This article explores the different types of plywood, including their unique features and uses.

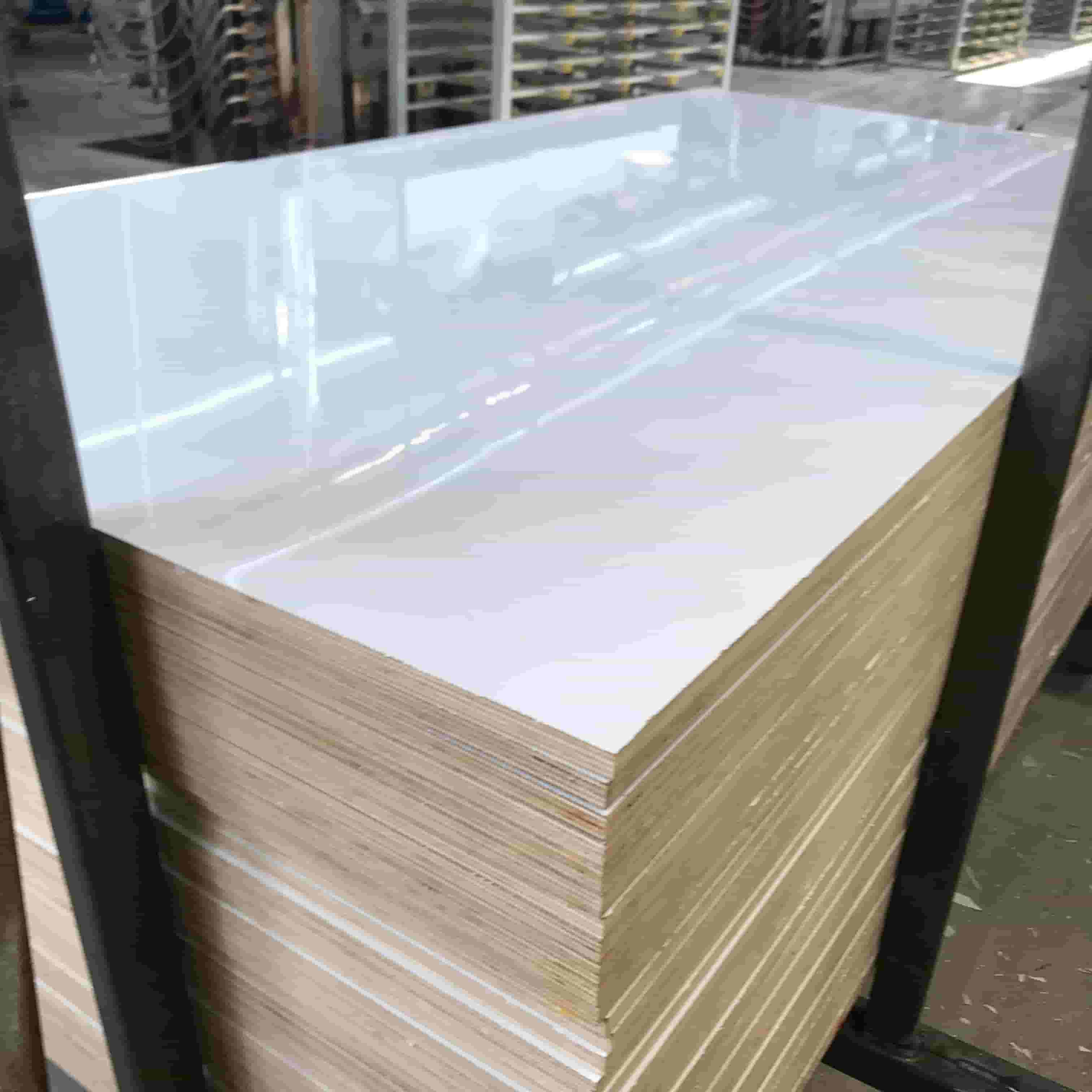

Engineered wood, also known as composite wood, is produced by bonding or laminating multiple layers of wood veneers using adhesives. One common type is the 4×8 1/2 inch poplar plywood, which is made from thin slices of poplar wood that are glued together with adjacent plies having their grains running perpendicular to each other for added strength. This size and thickness make it perfect for general construction tasks like sheathing, subflooring, and wall paneling.

Multiplex board is another variety of plywood that consists of multiple thin layers of wood, where each layer’s grain direction alternates. This crisscross pattern enhances its stability and resistance to warping. It is an excellent choice for heavy-duty applications such as flooring, roofing, and concrete formwork because of its superior durability and load-bearing capacity.

Chinese flakeboard, also referred to as strand board, is manufactured by compressing wood strands that are coated in adhesive. Unlike traditional plywood, which uses thin sheets, flakeboard employs much shorter pieces of wood. This process results in a more uniform texture and a stronger bond between the particles. Flakeboard is often used in areas with high moisture due to its good resistance to water absorption.

Original Design Manufacturer (ODM) plywood stands out for its quality control and production processes. ODM manufacturers specialize in creating custom plywood solutions according to client specifications, ensuring precise dimensions, desired wood species, thickness, and finish. This tailored approach makes ODM plywood suitable for specialized applications where standard sizes and qualities won’t suffice.

In conclusion, understanding the different types of plywood enables users to select the most suitable product for their specific needs, considering factors such as durability, size, thickness, and water resistance. From general construction uses to specialized applications, there is a type of plywood designed to meet various requirements efficiently.